Types of Butterfly Valves

At Curtiss Wright, we hold a variety of butterfly valves for many applications. They can come in diverse designs, each of which serves specific environments and pressure ranges. Butterfly valves are categorized based on their disc closure design, connection design, and actuation method.

There are three common types of butterfly valves, zero offset, double offset, and triple offset.

Zero-Offset Butterfly Valve

A zero offset butterfly valve is known for its concentric design and is often called resilient seated or rubber seated butterfly valves. They rely on the flexibility of rubber to create a seal. The valves have the lowest pressure rating and include a stem and disk centered in the seat and body of the valve. The fully protected seat is used to reduce the risk of any solids damaging the seating surface.

Zero-Offset Butterfly Valve Applications

A zero-offset butterfly valve is commonly used in applications such as handling:

- Chemicals

- Coatings

- Abrasive

- Food

Double-Offset Butterfly Valves

Used mainly for their shut-off and throttle control, high-performance double offset butterfly valves are designed to handle anything from general applications to corrosive liquids and gases. A double offset is used for higher pressures than the zero offset valves.

Valve Design

The valve has two stems offset from the center, creating a cam action when in use. One is offset from the centerline of the disk seat and body seal. The seat is lifted out of the seal, reducing friction resulting in less wear. The other is offset from the centerline of the bore.

Double-Offset Butterfly Valve Applications

A double offset butterfly valve is commonly used in:

- Power generation

- Chemical

- Oil

- Gas

- Wastewater treatment

- Shipbuilding

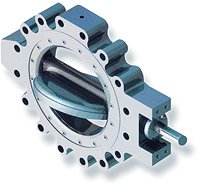

Triple Offset Butterfly Valves

Similar to the positioning of a double offset valve, the triple butterfly valve also has a third offset due to the seating surface’s positioning. Using this method allows the disc to seal against the seat without causing any friction.

The uniform sealing allows for a tight shutoff in a metal seat design and is famous for its low cost and low torque requirements.

Triple-Offset Butterfly Valve Applications

A triple offset butterfly valve is commonly used for:

- High-pressure steam

- Superheated steam

- High-temperature gases and oils